E-mail. Email:foodmachinery@heyingmachinery.com

Tel. +86 18366531276

E-mail. Email:foodmachinery@heyingmachinery.com

Tel. +86 18366531276

PROADUCT LIST

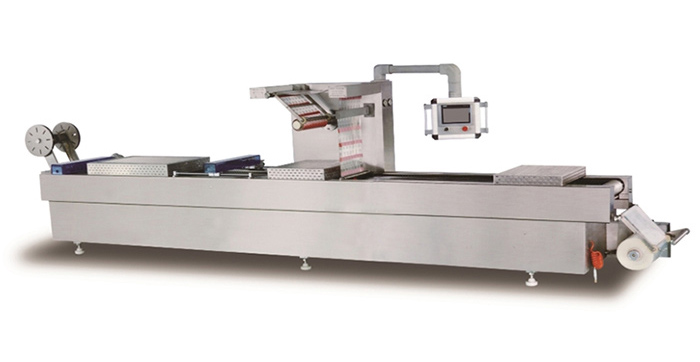

Stretch Film Vacuum Packaging Machine

Product Description

Stretch Film Vacuum Packaging Machine is also called thermoforming stretch film vacuum packaging machine.It is a type of packaging equipment that is used to vacuum pack products using stretch film. The machine uses a vacuum pump to remove the air from the packaging, creating a vacuum seal. The stretch film is then wrapped tightly around the product, providing a secure and protective layer of packaging. This type of packaging is commonly used for food products, as it helps to extend the shelf life and preserve the quality of the product.

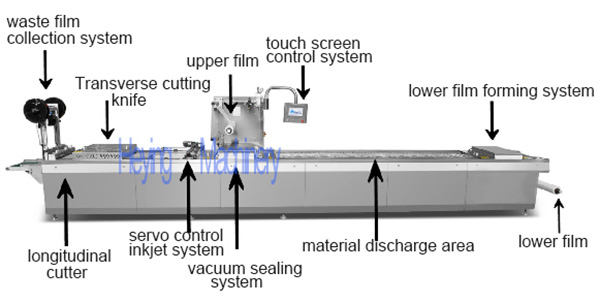

Machine Structure Introduction

Stretch Film Thermoforming Vacuum Packaging Machine is an automatic packaging equipment including film stretching forming, vacuum (air conditioning), heat sealing, injet code, segmentation, blanking conveying in a integrated machine.

Detailed Parts Introduction

1.The main beam of the automatic stretch film vacuum packaging machine is made of 6mm SUS304 stainless steel, with precise laser cutting, positioning, and punching. The modular screw assembly ensures more stable quality

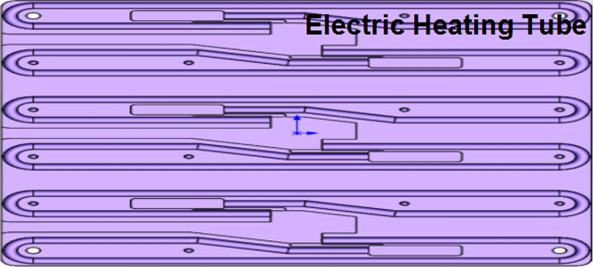

2.The is heated by 6 paper clips in a uniform manner, with low energy consumption, good heat sealing effect, and simple and convenient replacement.

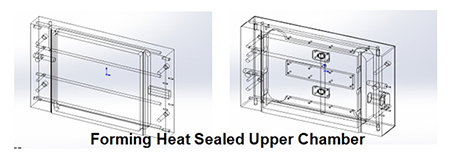

3.Forming heat sealed upper chamber, made entirely of 6061 alloy aluminum processing, with strong hardness and long service life. It is designed with water holes, and the radiated heat energy is carried out of the workshop through cooling water, saving energy and reducing consumption.

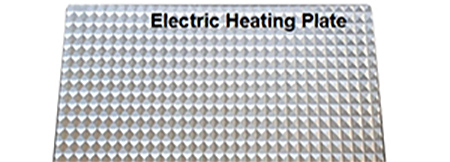

4.The electric heating plate has a concave and convex surface, which is well formed and not easily wrinkled.

5.The upper and lower films are fed by a brake motor and equipped with a handle type lateral film adjustment device, which evenly expands and brakes smoothly, avoiding wrinkling, curling, and other phenomena in the packaged products, achieving the best packaging effect. Fixed tension pre tensioning system, stable lower film pre tensioning system, well-designed emergency stop device and safety protection device.

6.Customize the overall cutting blade according to the user's product. When making different products, it is simpler and has no safety hazards. It only takes 30 seconds to use a hidden cutting blade to ensure the safety of the equipment during operation.

High safety protection level, quick and easy replacement of cutting blades. A longitudinal cutting blade device that can be safely and quickly replaced as a whole, equipped with a conveyor belt that can seamlessly connect with subsequent processes.

7.Programmable Servo Inkjet System

No ink required, optional servo control mobile device (robot), spray code on packaging items one by one. The sprayed date has a longer storage time, is clearer and more visible, and the appearance is also more beautiful and elegant.

8.Forming and heat sealing:

The lifting system of the forming and heat sealing molds is a knee bending eight link lifting system. The lifting device is made of 6061 aviation aluminum alloy precision machining, which increases the stability and strength of the components.

9..Control System

Using French Schneider PLC computer control; French Schneider true color human-machine interface touch screen, control screen push-pull design;The Schneider servo system in France controls the high-speed and high-precision servo speed, ensuring beautiful film forming and heat sealing during the production process.

10.Waste edge recycling system

Adopting a low-power torque motor system, the torque of the waste edge recycling motor can be adjusted at any time. Make waste edge collection more convenient, simple, and noise free, convenient and durable.

Application

The food industry is one of the main application areas of stretch film vacuum packaging machines. This kind of packaging machine is suitable for solid products, such as dried tofu, fish tofu, ass hide glue cake, Soy egg, areca, beef jerky, corn, etc. These products exist in a single form, and are suitable for packaging with continuous stretch film vacuum packaging machine.

In addition,the pharmaceutical industry is also an important application area for stretch film vacuum packaging machines. Pharmaceutical products, such as infusion bags, syringes, etc., are often packaged using continuous stretch film vacuum packaging machines.

Inquire Now

Contact Us

Request a Quote

Links:

Copyright © Shandong Heying Machinery Technology Co., Ltd. 2024 All rights reserved